Anti-yellowing matting agent for interior powder coating T-323A

1.Description

T-323A is a wax-free matting hardener based on resin designed for hybrid powder coatings. T-323A can produce down to 8% of gloss matt coating at dosage 0.5-2%. Compared with the typical X68 type matt hardener, ①T-323A can provide excellent anti-yellowing, color stability, and gloss stability when over baking, strongly recommend using in matt powder coating of light color. ②T-323A can also provide good surface properties such as excellent flow, smoothness and fine silk feeling,and eliminate the finger marking .It’s available to use high polyester ratio to reach a good cost of formulation.

2.Typical physical data

|

Appearance |

pale yellow powder |

|

Soft range(℃) |

100-120 |

|

Bulk density (g/l) |

500-600 |

|

Solid content (%) |

>98 |

3.Suggested formula

|

Epoxy E-12 |

280 |

240 |

220 |

240 |

|

50/50polyester |

240 |

/ |

150 |

210 |

|

60/40 polyester |

/ |

280 |

/ |

/ |

|

70/30 polyester |

/ |

/ |

150 |

70 |

|

Levelling agent T-988 |

10 |

10 |

10 |

10 |

|

Appearance modifiers T-402 |

5-10 |

5-10 |

5-10 |

5-10 |

|

Pigment and filler |

420 |

420 |

420 |

420 |

|

Matting agent T-315 |

10-40 |

10-40 |

10-40 |

10-40 |

|

Curing condition:200℃×10min |

||||

4.Characteristics

①To obtain lower matting finish, normally select 50/50 polyester with slowly reactivity, as better mechanical performance and storage ability.

②Excess epoxy to matting agent ratio 1/1, the matting finish gloss lower, fullness and long-time shelf life.

③Worse storage ability than 68 matting system, please prevent store it in high temperature (>35℃)environment for a long time.

④T-315/ T -323A compared with similar products, characteristics as below:

A. Surface fullness B. excellent mechanical properties C. widely used in hybrid system

5.package and storage:

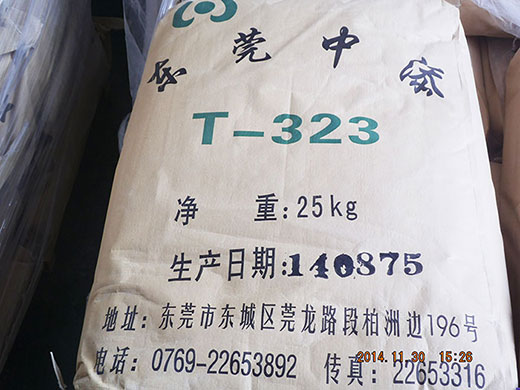

Packaging with PE lined Kraft paper bags, Net weight 25kg per bag. Store in cool and dry place to avoid moisture. According to our experience, the shelf life of this product is at least 2 years when ambient temperature below 30 ℃.